How to ensure the safe operation of the power system, prevent the occurrence of safety accidents, protect critical mission data from loss, and ensure the safety of personnel and equipment have always been the top priority of factory safety production. WAGO has a mature DC side ground fault detection solution to provide protection for the safe operation of the power supply system.

Ground fault detection is an important step in detecting system ground faults. It can detect ground faults, welding faults, and line disconnections. Once such problems are found, countermeasures can be taken in time to prevent ground faults from occurring, thereby avoiding safety accidents and property losses of expensive equipment.

Four major advantages of the product:

1: Automatic evaluation and monitoring: no manual intervention is required, and the normal operation of the equipment is not affected.

2: Clear and clear alarm signal: Once an insulation problem is detected, an alarm signal is output in time.

3: Optional operation mode: It can meet both grounded and ungrounded conditions.

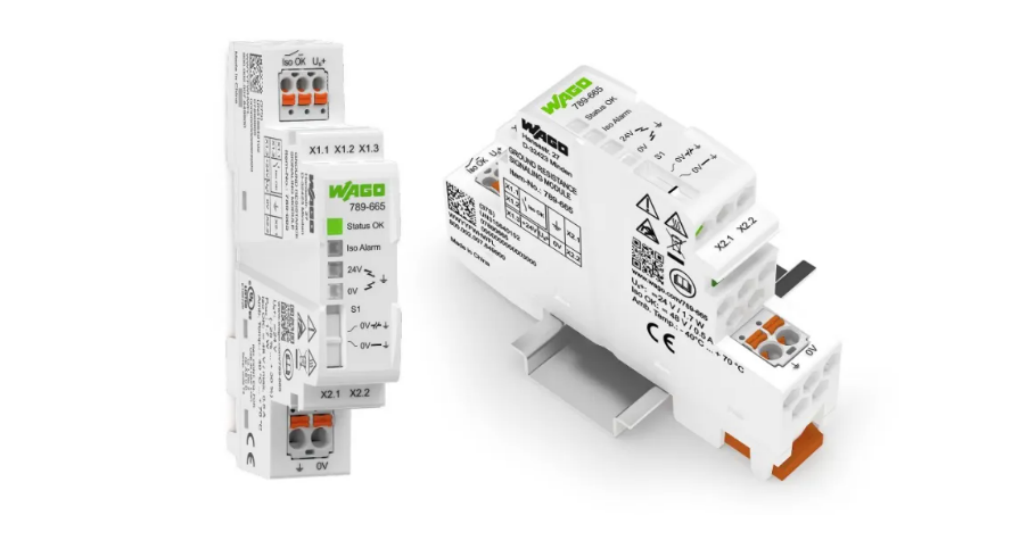

4: Convenient connection technology: The direct plug-in connection technology is used to facilitate on-site wiring.

WAGO Example Applications

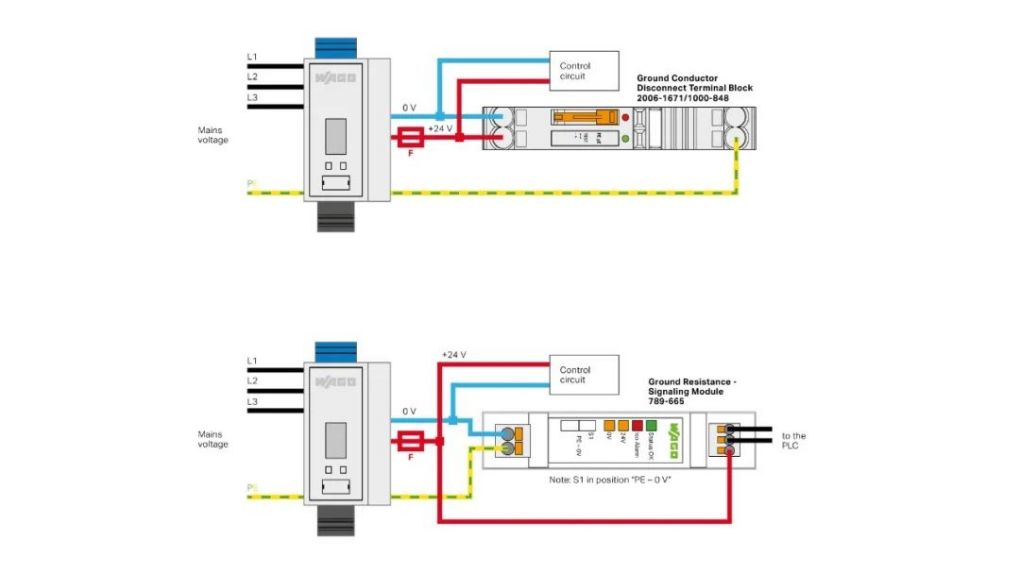

Upgrading from Protective Ground Disconnect Terminal Blocks to Ground Fault Detection Modules

Whenever protective ground disconnect terminal blocks are used, the ground fault detection module can be easily upgraded to achieve fully automatic monitoring.

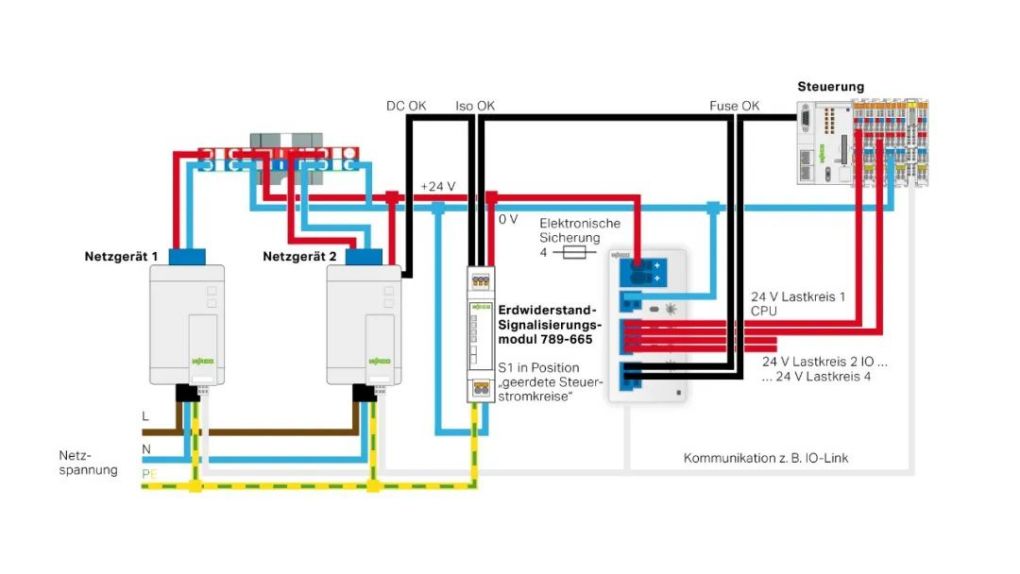

Only one ground fault detection module is needed for two 24VDC power supplies

Even if two or more power supplies are connected in parallel, one ground fault detection module is sufficient to monitor ground faults.

From the above applications, it can be seen that the importance of DC side ground fault detection is self-evident, which is directly related to the safe operation of the power system and the protection of data. WAGO's new ground fault detection module helps customers achieve safe and reliable production and is worth purchasing.

Post time: Sep-14-2024