Paper bags not only appear as an environmental protection solution to replace plastic bags, but paper bags with personalized designs have gradually become a fashion trend. Paper bag production equipment is changing towards the needs of high flexibility, high efficiency, and rapid iteration.

In the face of an ever-evolving market and increasingly diverse and demanding customer needs, the solutions for paper bag packaging machines also need rapid innovation to keep pace with the times.

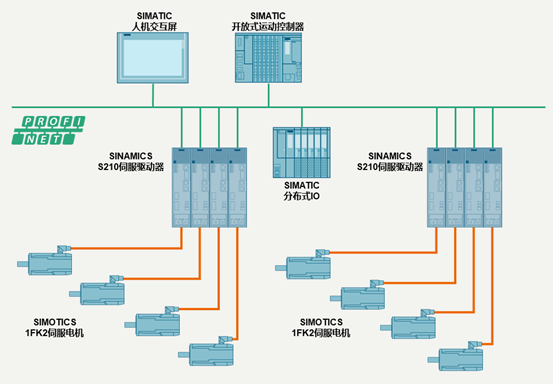

Taking the most popular cordless semi-automatic square-bottom paper bag machine on the market as an example, the standardized solution consists of SIMATIC motion controller, SINAMICS S210 driver, 1FK2 motor and distributed IO module.

Personalized customization, flexible response to different specifications

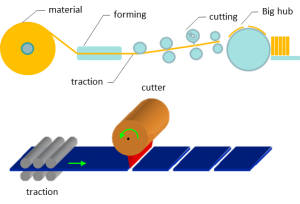

The Siemens TIA solution adopts a well-designed double-cam curve scheme to plan and adjust the cutter running curve in real time, and realize online switching of product specifications without slowing down or stopping. From the change of paper bag length to the switch of product specifications, the production efficiency is significantly improved.

Precise cut to length, material waste is minimized

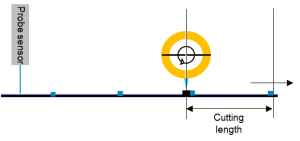

It has two standard production modes of fixed length and mark tracking. In the mark tracking mode, the position of the color mark is detected by a high-speed probe, combined with the user's operating habits, a variety of mark tracking algorithms are developed to adjust the position of the color mark. Under the demand of cutting length, it meets the needs of ease of use and operability of the equipment, reduces the waste of materials and saves production costs.

Enriched motion control library and unified debugging platform to accelerate time-to-market

The Siemens TIA solution provides a rich motion control library, covering various key functional process blocks and standard motion control blocks, providing users with flexible and diverse programming options. The unified TIA Portal programming and debugging platform simplifies the tedious debugging process, greatly shortens the time for equipment to be put into the market, and allows you to seize business opportunities.

The Siemens TIA solution perfectly integrates personalized paper bag machines with efficient production. It addresses flexibilities, material waste and long commissioning times with elegance and precision, meeting the challenges of the paper bag industry. Make your production line more flexible, improve production efficiency, and meet the diverse needs of users for paper bag machines.

Post time: Jul-13-2023